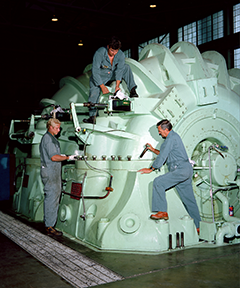

5334 - Marine Machinery Mechanic

Federal Occupation Description

Federal Occupation Description

This standard covers nonsupervisory work involving the dismantling, repairing, relocating, modifying, maintaining, aligning, and installing of a wide variety of marine machinery, equipment, and systems such as propulsion machinery, propellers, rudders, cargo handling machinery, lifeboat davits, anchor handling gear, and missile tube equipment that are located aboard submarines, ships, and other floating craft. The work requires a practical knowledge of the mechanical, hydraulic, and pneumatic systems and components of diverse marine machinery and their attachments. This includes detailed knowledge of the operating characteristics of the involved machinery, equipment, and systems; their functional relationships; the applicable installation and repair procedures, methods, and trade practices; and the unique environmental conditions under which work is performed aboard marine craft, for example, the lack of space between bulkheads and decks and the proximity of one type of machinery to another.

For job opportunities in this series, go to the Office of Personnel Management USAJOBS website.

Other Federal Occupations

It is not uncommon for individuals in one federal occupational series to perform duties related to another series within the same federal occupational group. To find out about the certifications for another series in the INDUSTRIAL EQUIPMENT MAINTENANCE FAMILY, click on that series below. Note that credentials have not yet been identified for all series – links are provided only to those series for which the identification of credentials has been completed. Additional series will be added over time.

- 5301 - Misc Industrial Equipment Maintenance

- 5306 - Air Conditioning Equipment Mechanic

- 5309 - Heating and Boiler Plant Equipment Mechanic

- 5310 - Kitchen/Bakery Equipment Repairing

- 5313 - Elevator Mechanic

- 5317 - Laundry and Dry Cleaning Equipment Repairing

- 5318 - Lock and Dam Repairing

- 5323 - Oiling and Greasing

- 5350 - Production Machinery Mechanic

- 5352 - Industrial Equipment Mechanic

- 5378 - Powered Support Systems Mechanic

The following certifications have been identified as most relevant to the broad duties of this federal occupational series. Please note that these credentials may not reflect all of the unique job functions that you perform within your organization. Also these credentials may require additional education, training or experience. For more information about any credential, click on the credential title below.

| Compare | Credential | Agency | Related As | GI Bill® | Accreditation | ID | |

|---|---|---|---|---|---|---|---|

| Fluid Power Connector and Conductor (CC) Is Not In Demand | International Fluid Power Society (IFPS) |  Some Some |

|||||

| Fluid Power Engineer Is Not In Demand | International Fluid Power Society (IFPS) |  Some Some |

|||||

| Hydraulic Specialist (HS) Is Not In Demand | International Fluid Power Society (IFPS) |  Most Most |

GI Bill GI Bill |

||||

| Industrial Hydraulic Mechanic (IHM) Is Not In Demand | International Fluid Power Society (IFPS) |  Most Most |

GI Bill GI Bill |

||||

| Industrial Hydraulic Technician (IHT) Is Not In Demand | International Fluid Power Society (IFPS) |  Most Most |

GI Bill GI Bill |

||||

| Mobile Hydraulic Mechanic (MHM) Is Not In Demand | International Fluid Power Society (IFPS) |  Most Most |

GI Bill GI Bill |

||||

| Mobile Hydraulic Technician (MHT) Is Not In Demand | International Fluid Power Society (IFPS) |  Most Most |

GI Bill GI Bill |

||||

| Pneumatic Mechanic (PM) Is Not In Demand | International Fluid Power Society (IFPS) |  Most Most |

GI Bill GI Bill |

||||

| Pneumatic Specialist (PS) Is Not In Demand | International Fluid Power Society (IFPS) |  Most Most |

GI Bill GI Bill |

||||

| Pneumatic Technician (PT) Is Not In Demand | International Fluid Power Society (IFPS) |  Most Most |

GI Bill GI Bill |

||||

| Certified Control Systems Technician - Level I (CCST-I) Is Not In Demand | International Society of Automation (ISA) |  Most Most |

|||||

| Certified Lubrication Specialist (CLS) Is Not In Demand | Society of Tribologists and Lubrication Engineers (STLE) |  Most Most |

|||||

| Oil Monitoring Analyst - I (OMA-I) Is Not In Demand | Society of Tribologists and Lubrication Engineers (STLE) |  Some Some |

|||||

| Certified Equipment Manager Is Not In Demand | Association of Equipment Management Professionals |  Some Some |

|||||

| Very Small Water System Operator Is Not In Demand | Association of Boards of Certification (ABC) |  Some Some |

|||||

| Certified Maintenance and Reliability Technician (CMRT) Is Not In Demand | Society for Maintenance and Reliability Professionals (SMRP) |  Most Most |

|||||

| Level I Machine Lubricant Analyst (MLA I) Is Not In Demand | International Council for Machinery Lubrication (ICML) |  Some Some |

|||||

| Level I Machine Lubrication Technician (MLT I) Is Not In Demand | International Council for Machinery Lubrication (ICML) |  Most Most |

|||||

| Level II Machine Lubrication Technician (MLT II) Is Not In Demand | International Council for Machinery Lubrication (ICML) |  Some Some |

|||||

| Certified Control Systems Technician - Level II (CCST-II) Is Not In Demand | International Society of Automation (ISA) |  Some Some |

State Licenses

Some states have specific licensing requirements for the following related civilian occupations. These state licenses may require additional education, training or experience. Click on the occupation below to get more information on state requirements from the U.S. Department of Labor.

- Control and Valve Installers and Repairers, Except Mechanical Door

- Electro-Mechanical Technicians

- First-Line Supervisors of Mechanics, Installers, and Repairers

- Heating and Air Conditioning Mechanics and Installers

- Heating, Air Conditioning, and Refrigeration Mechanics and Installers

- Industrial Machinery Mechanics

- Refrigeration Mechanics and Installers

Related Civilian Private Sector Occupations

The following civilian private sector occupations are similar to the duties performed by 5334 - Marine Machinery Mechanic. These occupations may require additional education, training or experience. For more information about these occupations, click on the civilian occupation below.

| Civilian Job | Duties Matched | Bright Outlook | Registered Apprenticeship | Local Salary Info | |

|---|---|---|---|---|---|

| Control and Valve Installers and Repairers, Except Mechanical Door |

Some Some

|

Apprenticeship Apprenticeship |

find local salary find local salary |

||

| Electro-Mechanical Technicians |

Some Some

|

Apprenticeship Apprenticeship |

find local salary find local salary |

||

| First-Line Supervisors of Mechanics, Installers, and Repairers |

Some Some

|

find local salary find local salary |

|||

| Heating and Air Conditioning Mechanics and Installers |

Some Some

|

Bright Outlook Bright Outlook |

Apprenticeship Apprenticeship |

find local salary find local salary |

|

| Industrial Machinery Mechanics |

Some Some

|

Apprenticeship Apprenticeship |

find local salary find local salary |

||

| Insulation Workers, Mechanical |

Some Some

|

Bright Outlook Bright Outlook |

Apprenticeship Apprenticeship |

find local salary find local salary |

|

| Mechanical Engineering Technicians |

Some Some

|

Apprenticeship Apprenticeship |

find local salary find local salary |

||

| Mobile Heavy Equipment Mechanics, Except Engines |

Some Some

|

Apprenticeship Apprenticeship |

find local salary find local salary |

||

| Motorboat Mechanics and Service Technicians |

Most Most

|

Apprenticeship Apprenticeship |

find local salary find local salary |

||

| Outdoor Power Equipment and Other Small Engine Mechanics |

Some Some

|

Bright Outlook Bright Outlook |

Apprenticeship Apprenticeship |

find local salary find local salary |

|

| Refrigeration Mechanics and Installers |

Some Some

|

Bright Outlook Bright Outlook |

Apprenticeship Apprenticeship |

find local salary find local salary |

In Demand

In Demand OTHER

OTHER Accreditation

Accreditation